Additive Manufacturing

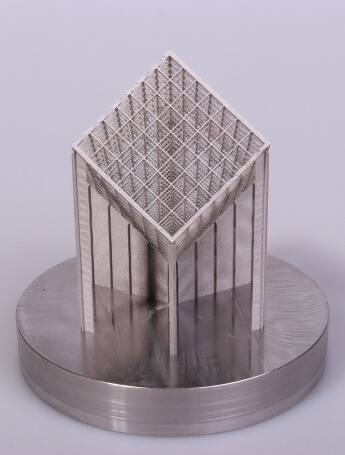

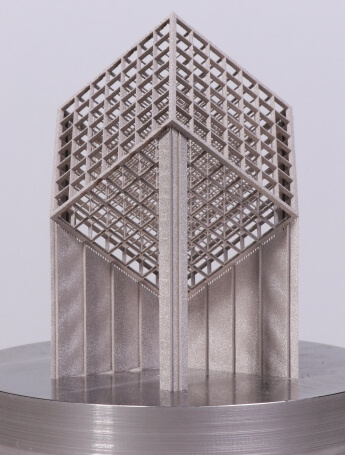

Since 2017 we are dealing with the manufacturing of 3D components made of metals, like stainless steel, titan or aluminum. This new technology, the Selective Laser Melting (SLM) process, enables the production of complete components layer by layer starting from a bed of metal powder. The 3D CAD model of the component is sliced up into single layers and the component is printed afterwards layer by layer. This allows the printing of complex component in a single production process, which was not possible before with traditional production methods. The rapid prototyping process produces a workpiece without using a mold for casting or milling, exclusively on the base of the 3D CAD data. The advantages of the additive manufacturing are all over all in the production of very complex geometries and structures and in the implementation of filigree forms. Preferred applications fields are in the medicine industry, mechanical- and tooling industry, aerospace industry and automotive industry.

![[Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision [Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision](/fileadmin/_processed_/7/c/csm_Imagebild_Laserabtrag3_83932edea1.jpg)