NanoWork ® - stencil with anti-adhesion properties

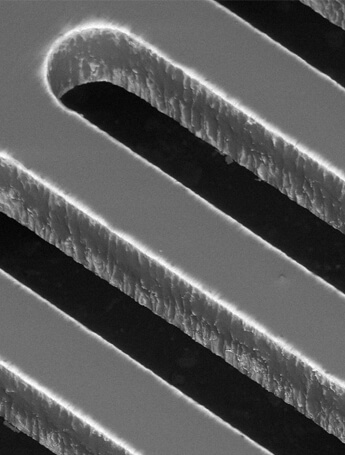

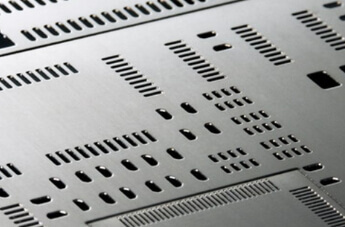

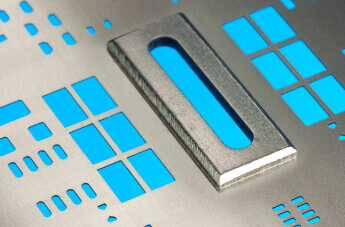

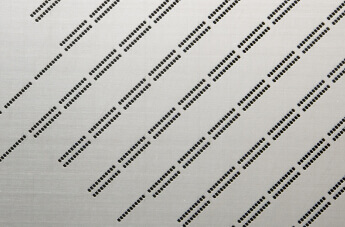

Laser cut stainless steel stencil with nano coating from LaserJob

The patented NanoWork - stencil from LaserJob is based on a laser cut SMD stencil. Since 2007 LaserJob coates SMD - stencils and step stencils in an in-house process. The NanoWork coating is applied on the bottom side of the SMD stencil and inside the apertures; the squeegee side stays uncoated.

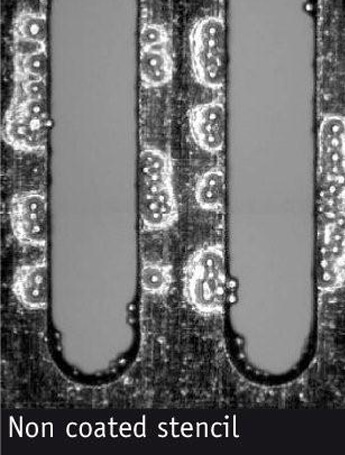

Better contour definition and lower failure quote

The unique “easy-to-clean” surface of the Nanowork - stencil reduces significant the adhesion of the solder paste on the bottom side of the SMD stencil and inside the apertures. Therefore the contour definition of the solder paste deposit is improved and constant transferred solder paste volumes are realized. Solder paste bridging is minimized as well, which leads to a higher process stability and lower failure rates.

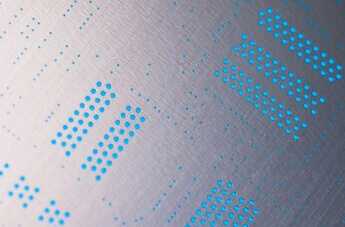

![[Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision [Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision](/fileadmin/_processed_/7/c/csm_Imagebild_Laserabtrag3_83932edea1.jpg)