Laser deposition- and repair welding

Form and tool maintenance with laser repair welding

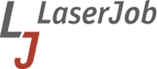

With our flexible pulsed Nd-Yag laser we are able to weld laserspots with a diameter of 0.2–2.0 mm. Therefore we are in the position to repair small cracks or large areas of stamping tools or injection molding tools. With the turn and tilt objective together with the rotary axis modul we perform horizontal to vertical rotations for a completely welding process.

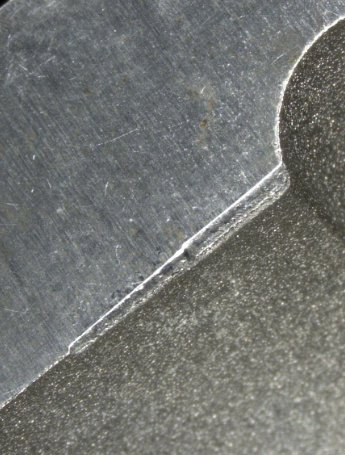

Laser deposition welding with wire additive

During the manual welding process a wire additive is positioned by hand to the welding area. In this way we build up material point by point, line by line or layer by layer to the desired geometry. With post processing like polishing, turning, milling or EDM we reconstruct the original shape of the tool.

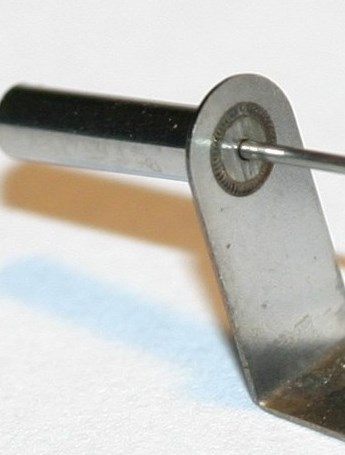

![[Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision [Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision](/fileadmin/_processed_/7/c/csm_Imagebild_Laserabtrag3_83932edea1.jpg)