Repair stencils and Reballing stencils in a lasercuting and laserwelding production process

Repair stencils and Reballing stencils in a laser cutting and laser welding production process

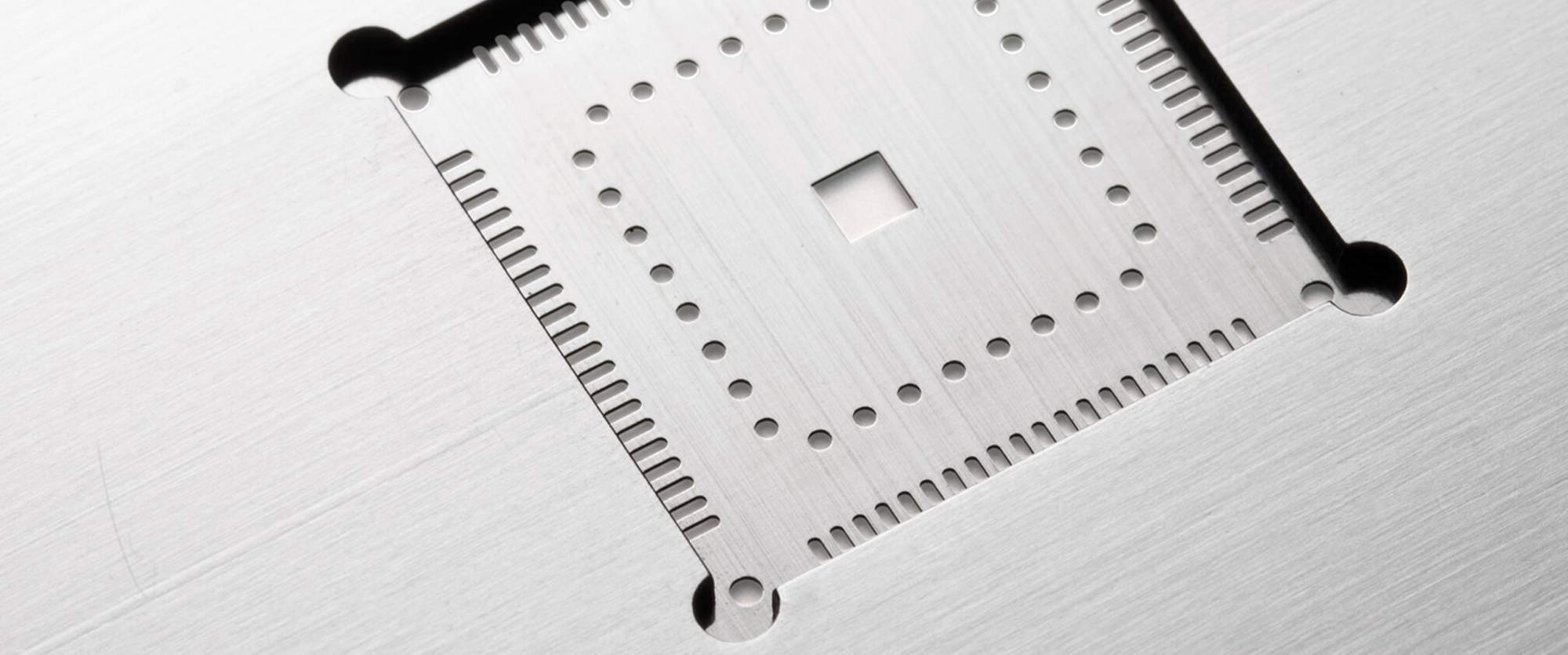

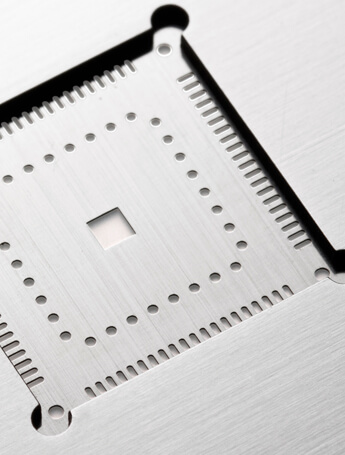

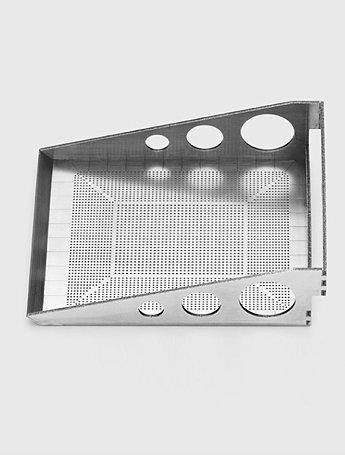

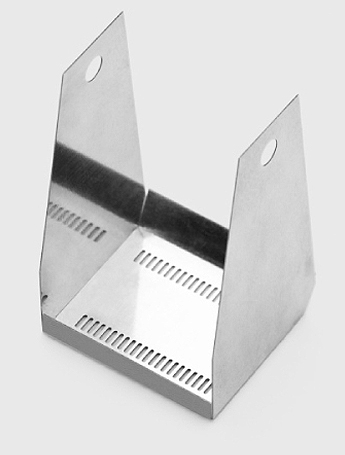

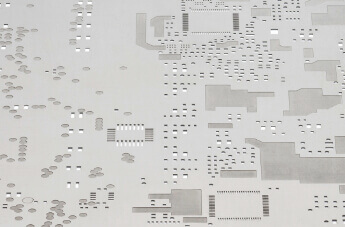

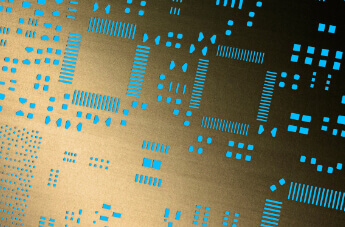

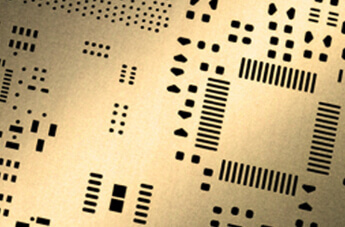

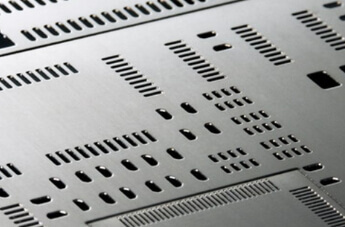

Since more than 10 years LaserJob is manufacturing repair stencils in a lasercut and laserwelding process. With the introduction of the SMD – Technology the constantly variety of component forms and component leads constantly increases, especially of the area array components, of the rework systems and of the repair stencils. The ever smaller becoming pitch - distance from component leads - represents a further challenge at the repair systems and repair stencils. In air controlled production rooms LaserJob is manufacturing repair stencils for all repair systems and repair stations. In strained conditions apertures and pad areas are cut in a stainless steel foil and a frame is welded on in the correct position. With this procedure we ensure that the sensitive stencil foil is protected against external damage and is present in strained conditions.

![[Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision [Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision](/fileadmin/_processed_/7/c/csm_Imagebild_Laserabtrag3_83932edea1.jpg)