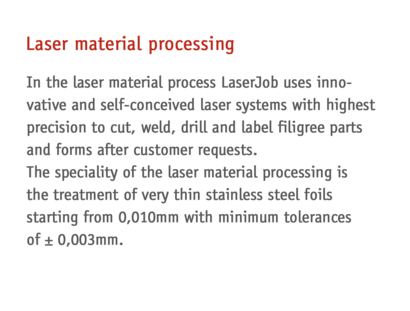

Laser cutting

We laser cut in micro dimensions.

With a working surface of 600 x 800 mm we laser cut with high-performance Nd-YAG-laser extremely fine. Our micro exact and high focused laser material process leads to ideal and gentle treatment of the material and stands for little material distortion, minimum change in material properties and optimum contour definition.

Choice of material to be laser cut with our laser systems

By default, all materials and alloys as well as metal composite listed in table 1 (see data-sheet) can be processed in the given dimensions. For any enquiries for other metals please contact our specialists. By laser cutting very thin metal foils in metal thicknesses of 0,010-0,020 mm we recommend the use of a device. The device can be built in our facility.

![[Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision [Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision](/fileadmin/_processed_/7/c/csm_Imagebild_Laserabtrag3_83932edea1.jpg)