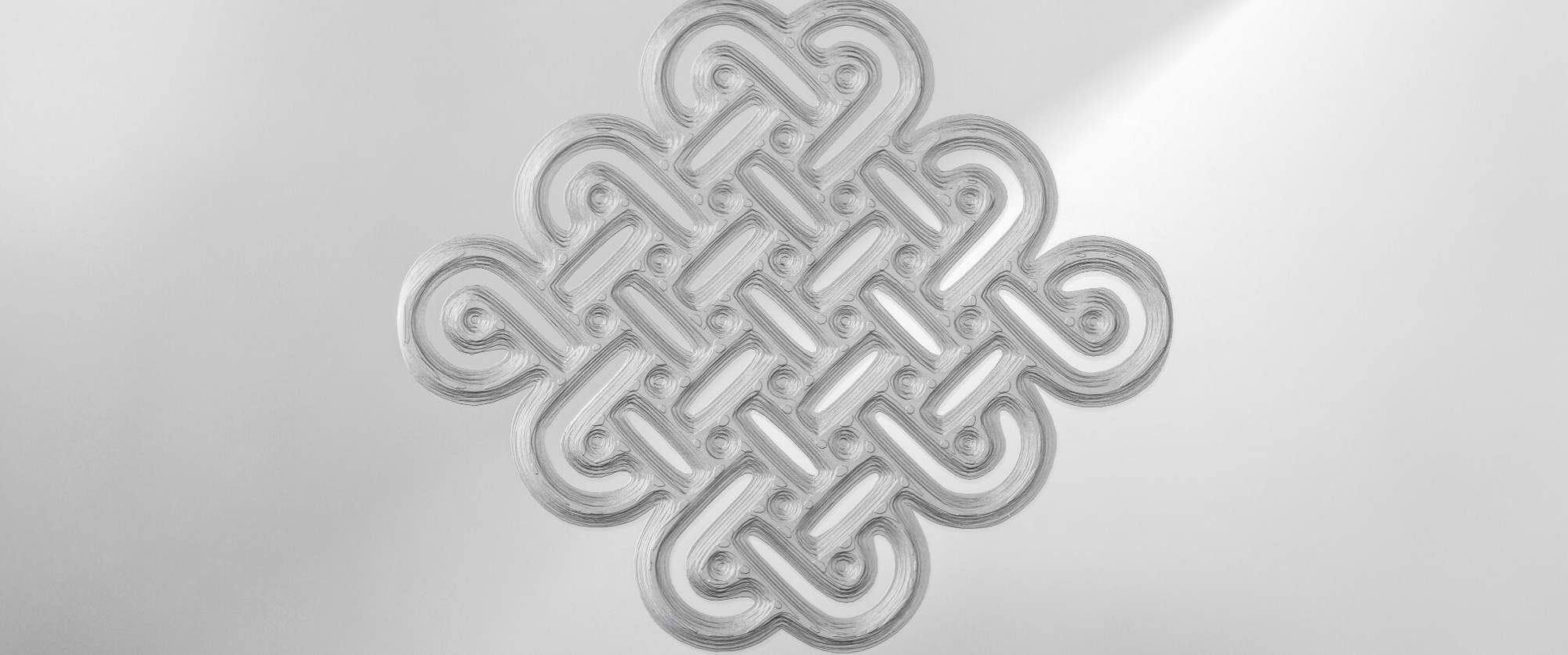

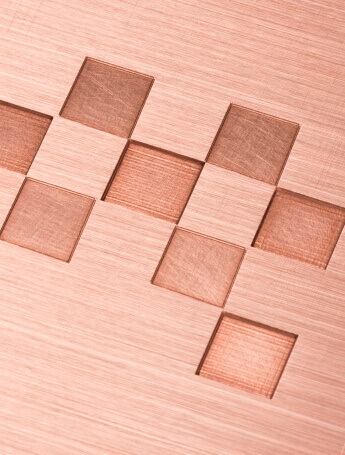

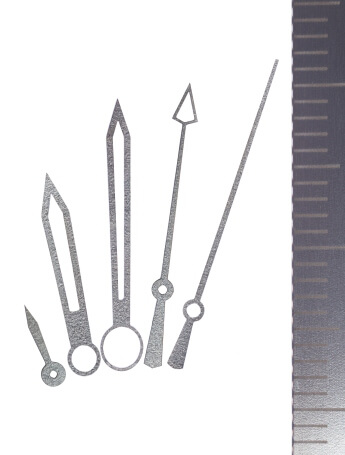

Laser ablation

Since 2011, LaserJob has utilized a new and innovative laser beam source which offers new

fields for laser ablation applications. With the development of an ultra-short pulsed laser (USP laser), the field of laser ablation applications expand. Pulses with a short duration of less than 15 ps (15 x 1012 s) and pulse peak power of several MW can show completely different absorption behaviors of the materials in the laser ablation process. Since heat conduction is no longer possible in such a short time, the molecule chains are broken off directly with the grid structure of the material.

Even materials which do not react with a wave length of 530 nm (green) (e.g. glasses, sapphires, etc.) are now possible to process with USP lasers. LaserJob’s USP laser even allows laser ablation, borehole drilling and structure surfacing of metal alloys.

![[Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision [Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision](/fileadmin/_processed_/7/c/csm_Imagebild_Laserabtrag3_83932edea1.jpg)