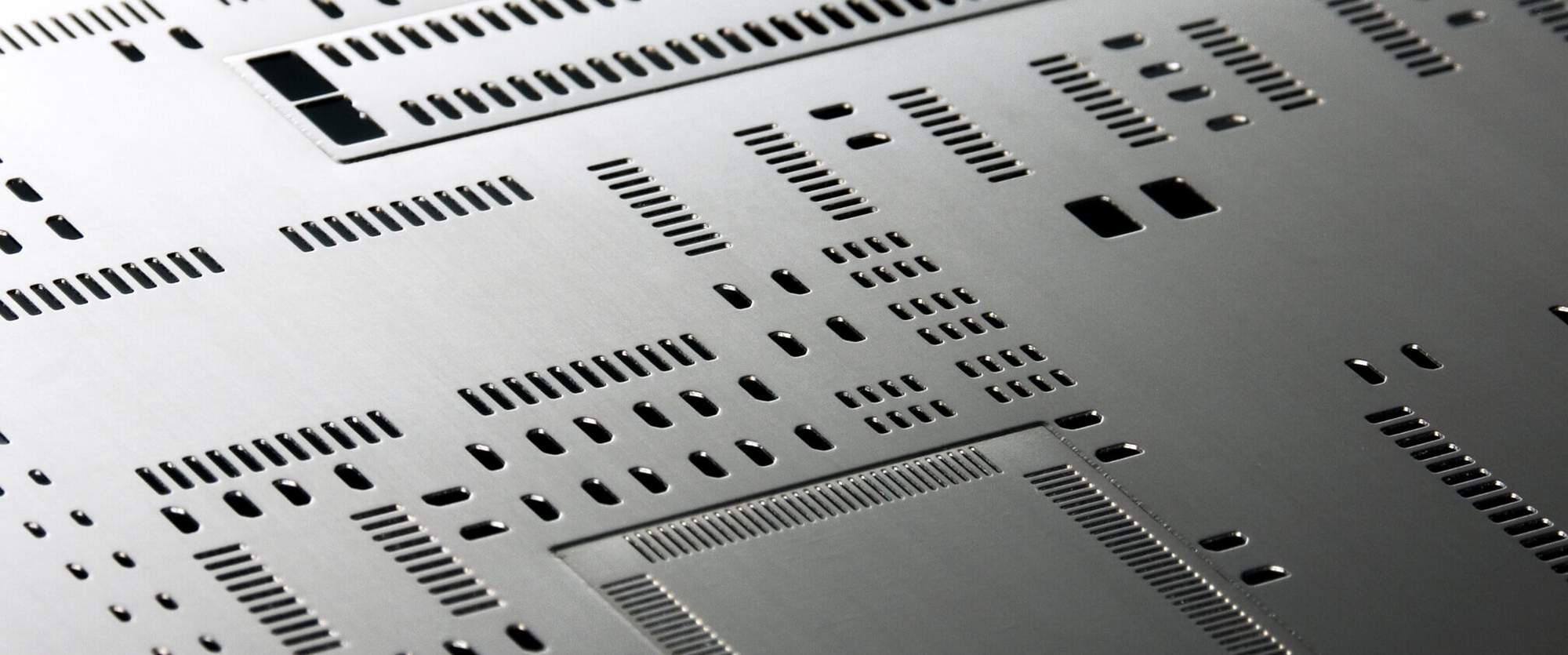

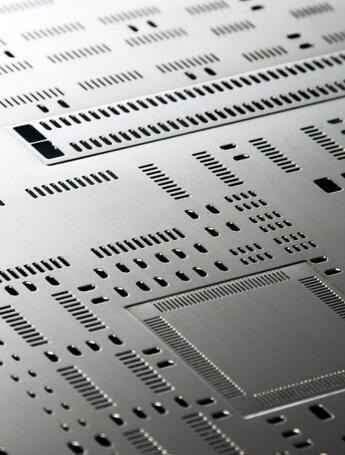

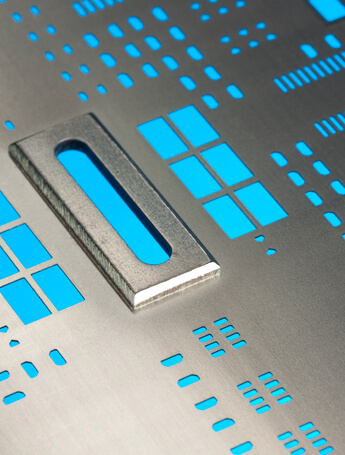

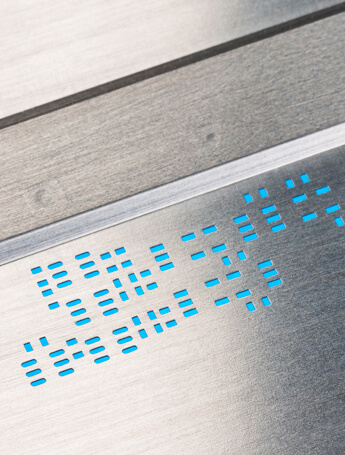

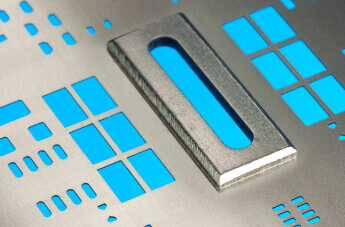

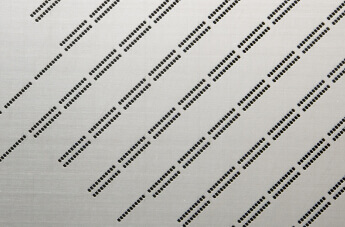

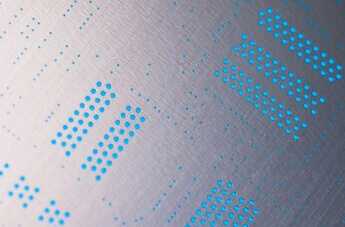

Laser cut step - stencil

tradename PatchWork®-stencil from LaserJob

The patented step stencil from LaserJob, called PatchWork® - stencil, was developed to print in one printing step different paste deposit heights. Due to the multiplicity of different component leads on one printed circuit board the recommended solder paste volume is not longer adjustable by the aperture size alone, but with different step heights in one stencil foil. A variety of the step stencil is the so called 3D - step stencil or 3D - PatchWork stencil, to print solder paste in deeper levels of a PCB. It is possible to print simultaneous on different levels with different solder paste deposit heights.

![[Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision [Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision](/fileadmin/_processed_/7/c/csm_Imagebild_Laserabtrag3_83932edea1.jpg)