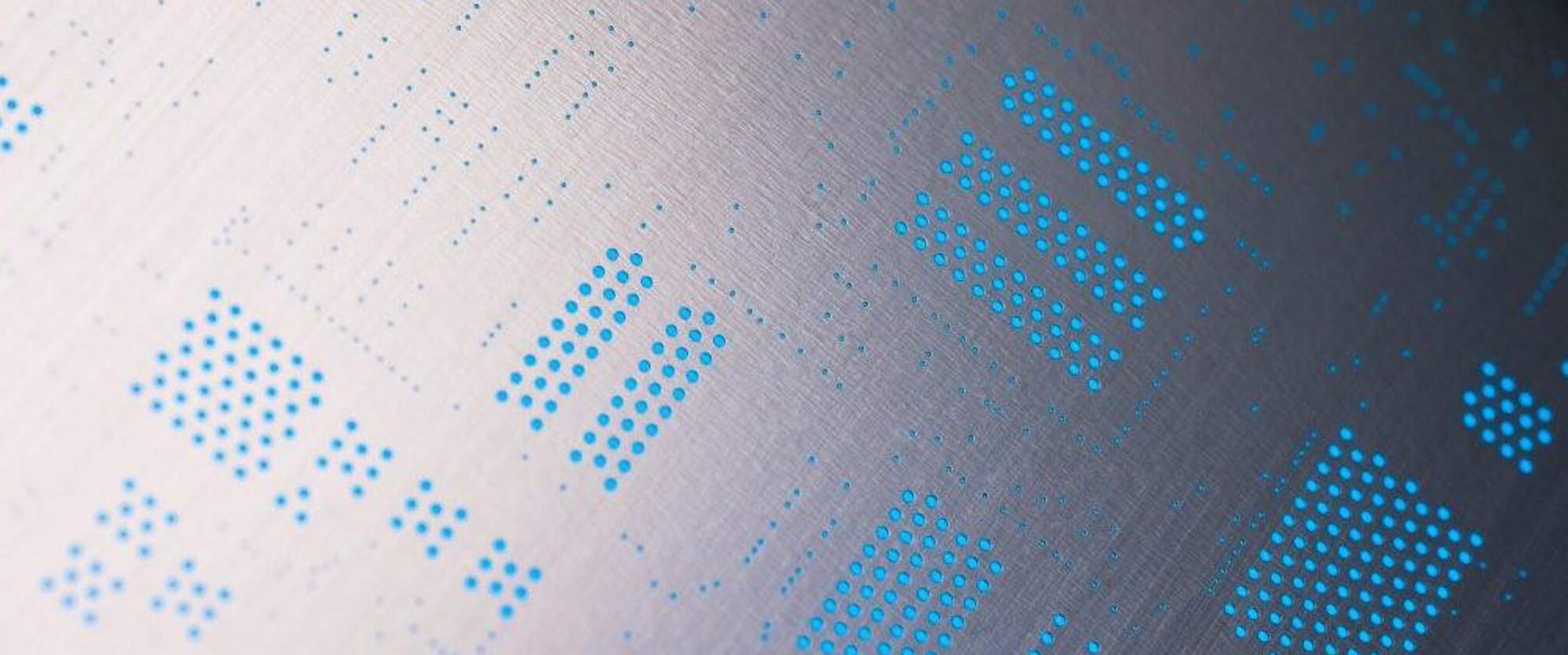

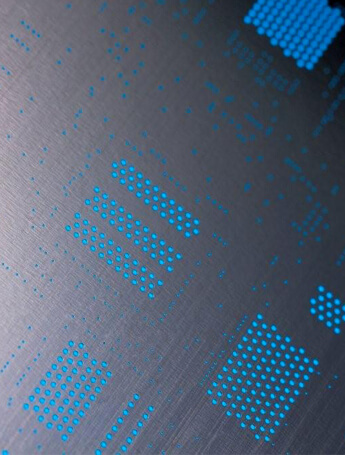

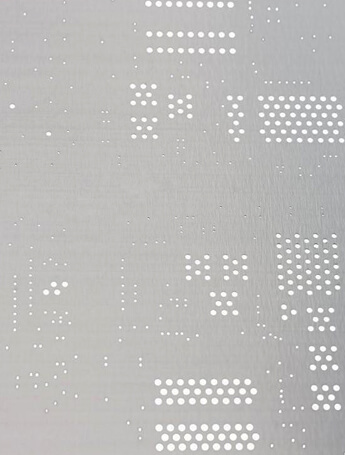

Via fill-stencil

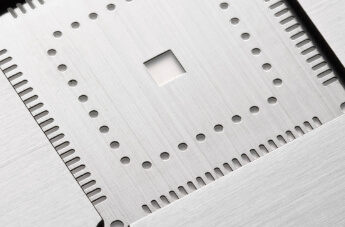

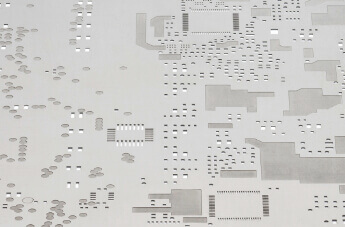

Lasercut LTCC-stencil (Low Temperature Cofired Ceramic)

The LTCC-technology (low temperature co-fired ceramic) is used in the hybrid-technique when several interconnection levels are realized. The connections between the layers are manufactured with very fine through-hole platings, the micro vias. A micro via is defined with a hole diameter of <300µm. The filling of the through-hole plating represents a special requirement on the accuracy of the Via fill - stencil. The Via fill - stencil shows thereby the function of a funnel, to print the silver conductive ink in the via. The positioning of the Vial fill - stencil to the hybrid and the maximum range of the tolerance of the deviation demand the minimization of the relevant tolerance limits from each process involved.

![[Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision [Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision](/fileadmin/_processed_/7/c/csm_Imagebild_Laserabtrag3_83932edea1.jpg)