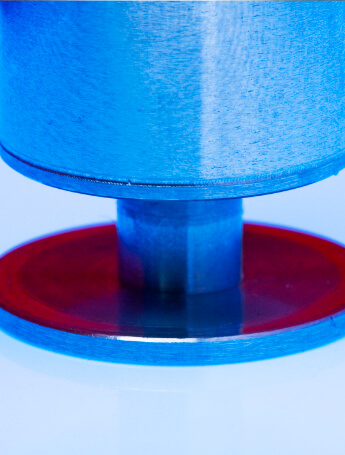

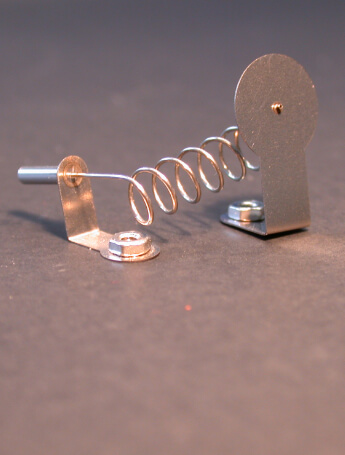

Laser welding

Perfect laser welding down to the smallest micro detail

The used pulsed Nd-YAG-Laser offers the possibility to laser weld parts and areas on micro levels solid and safe. The weld seams are always laser welded without the addition of material and are reliable interconnected without splice. With the focused/pulsed energy input of the laser beam you have the advantage of a low thermal stress and very low material distortion. With our laser systems we manufacture maximum laser welding depth of 0,8mm. With the 4 axes NC-control system, three of them with linear axes and one rotation axe we achieve optimal all-round welds. We produce from single pieces up to series production.

If a clamping device is necessary, we are able to construct and manufacture it. Typical laser welding applications are in the automotive industry, machine building and equipment industry as well as medicine- and electro industry.

![[Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision [Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision](/fileadmin/_processed_/7/c/csm_Imagebild_Laserabtrag3_83932edea1.jpg)