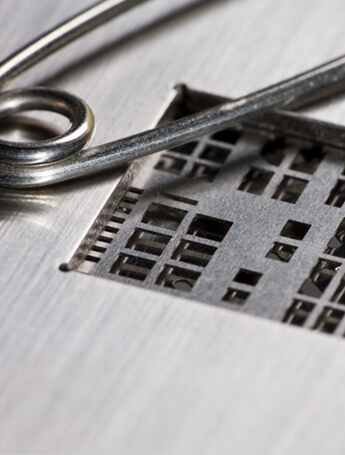

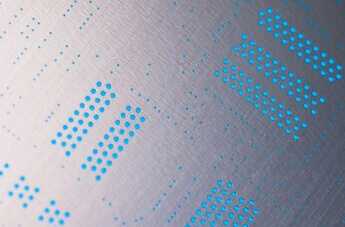

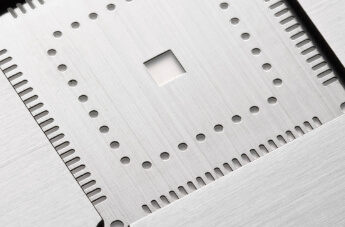

Laser cut 3D-step - stencil

tradename 3D-PatchWork®stencil

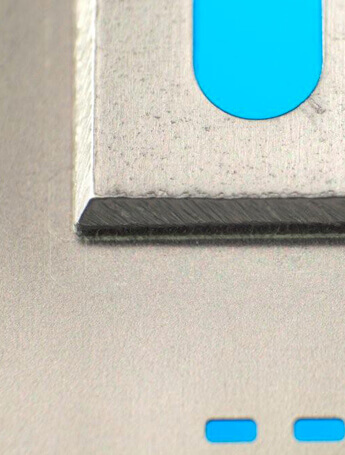

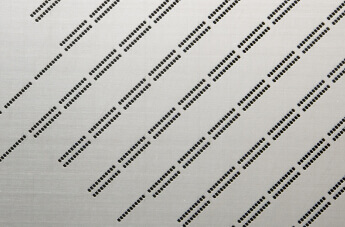

With the 3D-PatchWork® - stencil from LaserJob it is possible to print simultaneous on several levels of the PCB. Height differences from 10µm up to 2mm are realized with the PatchWork - Technology. At a height difference of >100µm we recommend a special squeegee blade which is adjusted to the cavity size.

![[Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision [Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision](/fileadmin/_processed_/7/c/csm_Imagebild_Laserabtrag3_83932edea1.jpg)