Laser material processing

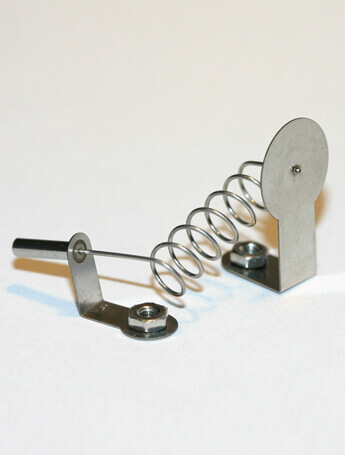

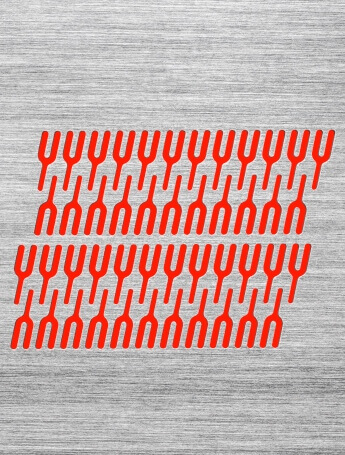

In the laser material process LaserJob uses innovative and self-conceived laser systems with highest precision to cut, weld, drill and label filigree parts and forms after customer requests. The speciality of the laser material processing is the treatment of very thin stainless steel foils starting from 0,010mm with minimum tolerances of ± 0,003mm. To guarantee a tight cutting opening of 20µm, mainly fiber lasers or pulsed Nd-YAG-lasers with the support of compressed air are in use, which are characterized by a reduced heat input into the material. We cut single components for you up to full-scale production with a working surface of 550 x 560 mm or 600 x 800 mm in the laser material process.

![[Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision [Translate to English:] Laser-Mikrobearbeitung - Höchste Präzision](/fileadmin/_processed_/7/c/csm_Imagebild_Laserabtrag3_83932edea1.jpg)